Our customer support is first class with trained engineers based in many countries to

Our customer support is first class with trained engineers based in many countries to

offer quick and reliable service.

PRODUCTS产品介绍

부 메뉴

현재 위치

Home > PRODUCTS > IBAD SystemIBAD System

We are making a company of trust with a unified heart.

We provide Optical Tech Products through Ion Beam Coating Systems.

The models are classified according to the functions and specifications of the product.

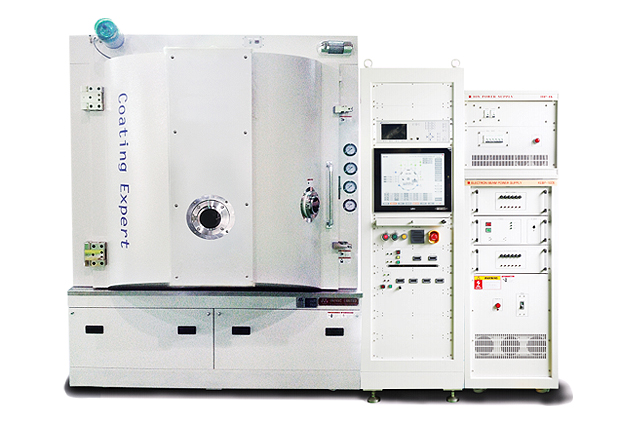

UNIVAC 1350

| System Model | UNIVAC-1350 | |

|---|---|---|

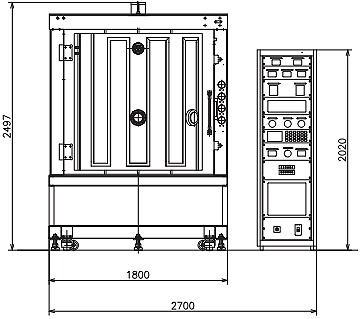

| Process Chamber | Ø1350×H1080 | |

| Pumping System | Diffusion | 22”×2sets |

| Mechanical booster Pump | 1,200㎥h-1 | |

| Oil Rotary Pump | 300㎥h-1 | |

| Meissner Trap | Polycold | |

| Substrate Carrier | Calotte Diameter | 1,296mm |

| Substrate Heating | Halogen Heater | Up to 250℃ |

| Evaporation Source | Electron Beam Source | 10kw |

| Thermal Source | 5kw | |

| Substrate Treatment | Ion Source | 4kw |

| Thin Film Thickness Monitioring |

Quartz Crystal Thickness Monitoring | SQM |

| Optical Thickness Monitoring(optional) | OPM | |

| Utility | Power | 3ph 380/220V |

| Freequency | AC 50/60Hz | |

| Power | 90kw(Max) | |

| Water Pressure | 2 ~ 4kgf/ ㎠ | |

| Air Pressure | 5 ~ 6kgf/ ㎠ | |

| Floor Load Weight | 4,500kgs(approx) | |

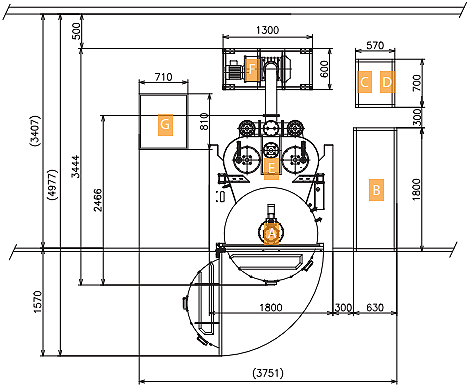

- AProcessing Chamber

- BSystem Controller

- CElectron beam power supply

- DIon beam power supply

- EHigh vacuum pump

- FLow vacuum pump

- GWater vapor cryocooler

Copyright(c) UNIVAC. All rights reserved.